Drawing on our experience in both manufacturing and project management, Fluid Wood Products is well suited to provide “turn-key” solutions to most building projects.

We have in-house engineers, drafts people, designers and logistics experts as well as experienced project managers who are experts in managing the installs of our prefabricated pine products. We value engineer the entire project from financial solutions, right through to manufacturing, shipping and installation.

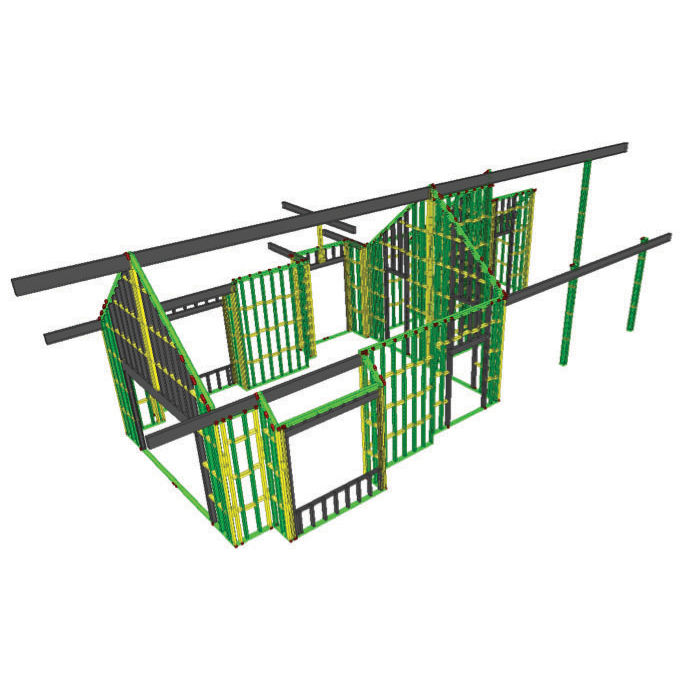

Our timber manufacturing plants are able to quickly bring your drawings to life

What’s Included

Our materials lists are always tailored to your project. A typical turnkey supply package may include:

- Foundations: Treated Timber Piles / RC Concrete

- Subfloor: Treated Timber Joists / Bearers / Plywood / Compressed Sheet

- Flooring: Selected Tile / Selected Hardwood

- Wall Framing: Treated Timber Framing / Pre-Cut Framing

- Roof Framing: Treated Timber Roof Framing / Pre-Cut Framing

- Exterior Cladding: Treated Timber Weather Board / Cement Board / Plywood / Select Finish

- Interior Lining: Cement Board / Plaster Board

- Fixings: Hot Dipped Galv / 316 Stainless Steel / Nails / Screws / Brackets / Custom Items

- Paints: Exterior Paint / Interior Paint / Timber Stains / Timber Preservtives / Undercoats

- Sundaries: Glues / Papers / Mesh / Compounds / Specialty Items

- Joinery: Treated Pine / Merbau / Oak / Glazing / Brio, Schlage Hardware